Self-adhesive labels

Number 1 on the market

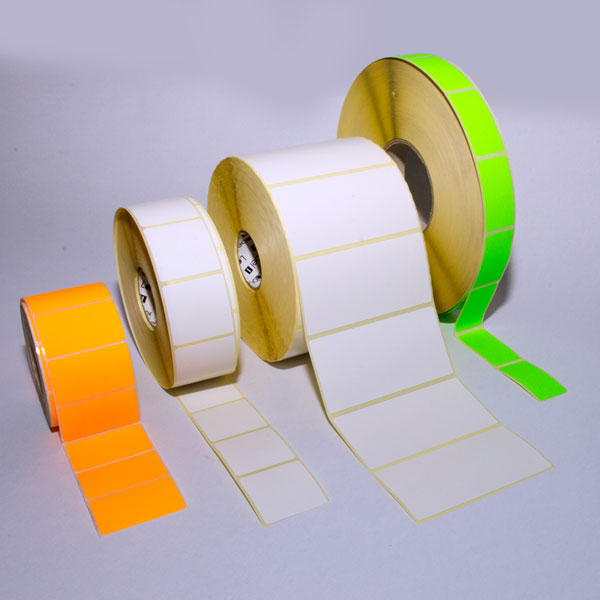

Self-adhesive labels are consumables for every type of printing devices using the thermal and thermal transfer technology. They are intended for various types of barcode and scale printers. They are available in a wide array of colors, with external and internal rolls on standard cores. The inner diameter of the core is 40 mm or 76 mm for company and industrial printers in amount per roll specified by the Customer or the maximum outer diameter possible in our recipient’s printer.

Labels are available with acrylic, natural rubber, easily-removable, deep-freeze, or special-purpose adhesive (e.g. metal, concrete, tires).

Our products are characterized by high-quality which guarantees the maximum lifespan of printing subassemblies (heads and platen rollers).

Thermal labels

Thermal labels are characterized by fast and easy method of thermal print. Labels of this type can be quickly applied and printed on in both thermal and thermal transfer printers. They are made of heat-sensitive paper. That is why the print does not require a thermal transfer ribbon. Due to the relatively low durability of overprint, this type of paper is recommended for labeling of products with short shelf life. Products are characterized by fast production and a proper quality-to-price ration. It must be highlighted that thermal labels with a longer expiry date are also available.

Products are manufactured based on the Customer’s requests and made of two types of paper:

Semi-gloss paper;

Matte paper;

Thermal paper;

The following adhesives are used to make the labels:

easily-removable adhesive;

acrylic adhesive (standard);

natural rubber adhesive (strong);

extra strong adhesive (for tires, carpets);

deep-freeze adhesive;

Thermal transfer labels

Thermal transfer labels are characterized by high durability of the print and great resistance to external factors, such as temperature, humidity, grease, and ultraviolet rays, depending on the used raw materials. They retain their resistance throughout the whole period of use of the labeled product. They are a very popular product on the market and are of great interest for the customers due to the wide range of applications and the cheapest print technology in the world.

Products are manufactured based on the Customer’s requests and made of two types of paper and various materials:

matte paper;

semi-glossy paper;

PP foil;

PE foil;

vinyl;

PVC;

The following adhesives are used to make the labels:

easily-removable adhesive;

acrylic adhesive (standard);

natural rubber adhesive (strong);

extra strong adhesive (for tires, carpets);

deep-freeze adhesive;

FOIL LABELS

In general, PP/PE foil labels provide greater durability compared to paper materials. They are also more resistant to water, grease, and chemicals. They are widely used in production of advertising and packaging materials.

polypropylene;

polyethylene;

nameplates;

Special purpose labels

Special purpose labels are adjusted to individual solutions typical of a particular application or sector of industry. Depending on the requirements, the label can consist of one or multiple layers while the tagging can be either permanent or temporary. Selection of materials and the shape of the label are determined by generally applicable standards and directives and based on the recipient’s specification.